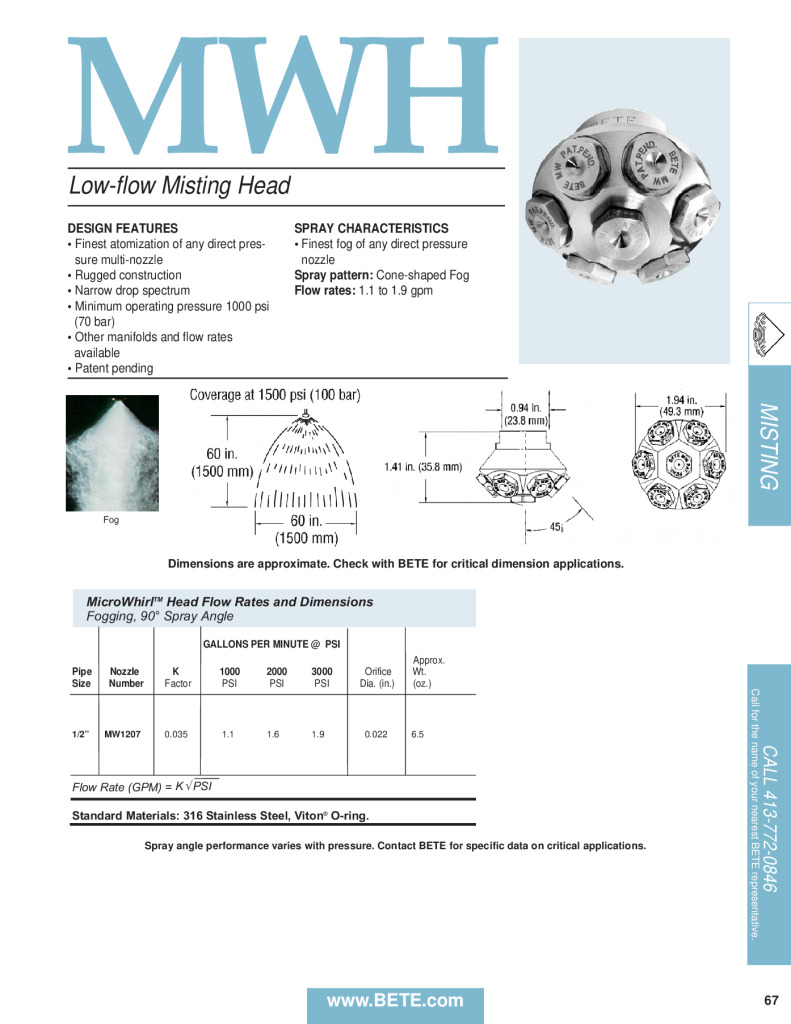

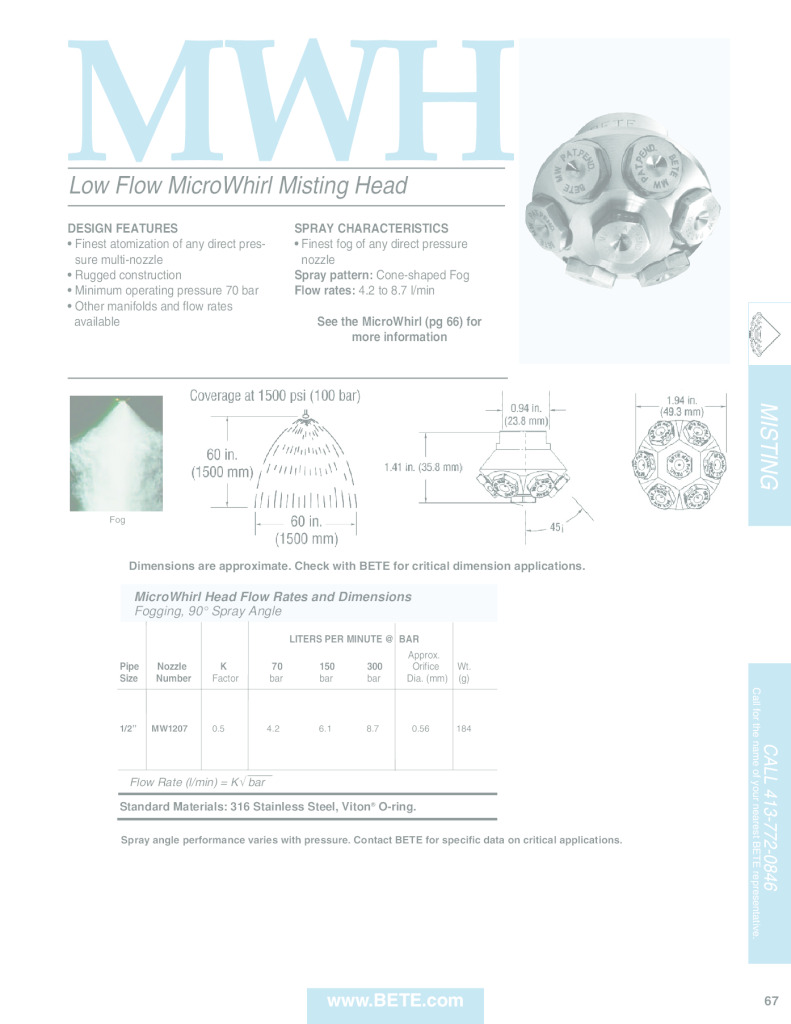

Bete MicroWhirl Head (MWH) Spray Nozzle : Low Flow Misting Head Nozzle

By using nozzles with very small orifices, a fine droplet size can be attained even at relatively low pressures. Misting nozzles utilize two main technologies; the first is the use of an impingement pin to achieve atomization, the second uses a very small whirl to achieve atomization. When used at higher pressures, direct pressure misting nozzles produce a droplet size that rivals air atomizing nozzles. The Bete MicroWhirl Head (MWH) spray nozzle is a standard, stock manifold for up to (7)individual MicroWhirl nozzles. These high pressure nozzles produce very low flow, and extremely fine misting protection.

Design Features of the Bete MicroWhirl Head (MWH) Spray Nozzle:

– Finest atomization of any direct pressure multi-nozzle

– Rugged construction

– Narrow drop spectrum

– Minimum operating pressure 1000 psi (70 bar)

– Other manifolds and flow rates available

– Patent pending

Spray Characteristics of the Bete MicroWhirl Head (MWH) Spray Nozzle:

– Finest fog of any direct pressure nozzle

Spray pattern: Cone-shaped Fog

Flow rates: 1.1 to 1.9 gpm (5.0 to 8.7 L/min)

Applications for the Bete MicroWhirl Head (MWH) Spray Nozzle:

– Fire Protection: Halon Replacement

– Fire Protection: Special (protect coal conveyors, fueling and vulcanizing cabinets, warehouses and munitions storage)

– Scrubbing: Conditioning (inject ammonia or water upstream of electrostatic precipitators; inject odor control additives)

Bete MicroWhirl Head (MWH) Spray pattern: