3M NB Monofilament Filter Bags are made of Polypropylene & Polyester. These bags provide cost effective solutions for applications where nominally rated bag filtration is appropriate. 3M Series NB bags are offered in Size #1 and #2 configurations in grades from 1 to 200 microns and fit into standard bag filter baskets and housings. The lightweight, low cost filtering material offers high chemical and corrosion resistance and has high contaminant holding capacity and the ability to remove both solid and viscous particles.

Applications for 3M Monofilament NB Filter Bags

- Amine Sweetening

- Completion & Workover Fluids

- Electrodeposition Paint

- Electrodeposition Paint Filtration

- Final Filtration for Particulates in Soft Drinks

- High Quality Paint Filtration

- Hydrotreater Feed

- Particle Reduction in Bottle Water Manufacturing

- Particle Reduction in Distilled Spirits Filtration

- Permeate Pre-UF, Pre RO Filtration

- Pretreatment

- Process Cooling Water

- Raw Material

- Intermediates & Feed Stream Filtration

- Resin Filtration

- Trade Paint Filtration

- Turbidity and Particle Control in Soft Drink Water

- Water Filtration for Wine Applications

- Water Injection for Enhanced Oil Recovery

Specifications:

| Brand | 3M™ |

|---|---|

| Diameter (In | Cm) | 7″ | 17.8 cm |

| Filter Material | Nylon Monofilament>, Polyester Felt, Polypropylene Felt |

| Filter Type | Bag Filter |

| Flow Rate (litres per min) | 340.7 lpm, 681.4 lpm |

| Industries | Industrial |

| Length (In | Cm) | 17″, 32″ | 43.2 cm, 81.28 cm |

| Micron Rating | 1 Absolute, @ 95%, 1 μm, 10 μm, 100 Absolute, @ 95%, 100 μm, 150 μm, 200 Absolute, @ 95%, 200 μm, 25 μm, 250 μm, 400 μm, 5 Absolute, @ 95% 5 μm, 50 μm, 600μm, 800 μm |

| Product Series | NB |

Features:

- Inside-Outside Flow Configuration, effectively captures contaminants on the inside

- Low unit-cost bags are collapsible for easy handling

- Material has the ability to handle viscous fluids

- Welded seams and thermally treated exterior surfaces for control of fiber migration

- Manufacturing processes do not include the use of silicone or adhesives for greater purity of filtered media

Consistent Filtration

3M uses welded Side Seams to form the bag and secure the sealing ring. Because there are no sewn holes there is no particle by-pass through the seam. Media migration is also controlled through thermal treatment of the exterior surface, which prevents material fibers from migrating into the clean, filtered process media. We then use state-of-the-art procedures to properly weld the seams and affix the media to the collar and form a complete, cohesive filter with no holes from sewing.

Plastic or Metal Ring

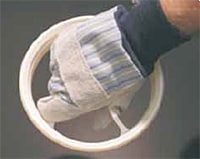

Proper sealing of the bag in the filter housing is necessary for prevention of fluid bypass and subsequent contamination of the downstream fluid. All of 3M™ Series NB Polyethylene and Polyester Filter Bags are offered in both plastic and metal ring sealing collar versions that will properly seal onto most filter bag manufacturers’ housings.

For plastic collar versions, 3M welds the filter bag media to a specially designed plastic collar to provide proper sealing of the 3M NB series filter bags in most conventional bag housings. The plastic collar incorporates an ergonomically designed handle allowing for easy removal of the filter bag from the filter housing. Handle designs also allow for insertion of bag accessories (displacement balloons, magnets, etc.) For ease of identification and traceability, we engrave the handles with micron grade and manufacturing lot information.

Metal ring collar versions use a galvanized steel ring for sealing the filter bag in the housing. These versions are appropriate for use in most filter bag housings that will not accept the plastic collar version.

Made to Filter

3M manufactures each felt filter bag grade from high performance fibers based on extensive media performance testing. They provide good to excellent chemical resistance to mineral acids, organic acids, alkalis, organic solvents, and microorganisms. All 3M NB series filter bags are ISO 9001:2008 certified and do not include silicone, binders, or adhesives. All polypropylene grades and specific polyester grades use materials that are listed for food contact per 21 CFR.