Custom Spray Nozzle Solutions – Gas Turbine Cooling

Application #091389

Industry: Power

Application: Gas Turbine Cooling

Product Description: Bete PJ Misting Nozzles

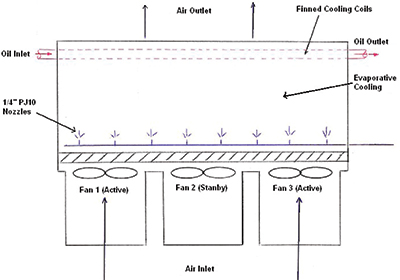

Situation: In the power industry, efficiency during peak demand is critical. As the temperature outside increases, the environment becomes less favorable to produce power. Inlet cooling at the intake of a turbine is a common form of increasing power output. The drawback is possible damage to the turbine if to much water is injected. A turbine compresses air as much as 40 to 1. Water is incompressible and this is where parts can be damaged. A customer came to Bete with an alternate application to increase cooling on a gas turbine. They want to use evaporative cooling across the coils used to cool oil that is used for lubricating and cooling the gas turbine. The added cooling increases power output. The customer has 6 gpm (23 L/min) at 3000 psi (210 bar) and limited space. The customer was able to provide the amount of airflow across the oil cooler coils provided by the fans, temperature, and humidity of the air for calculating cooling.

Solution: Using the customer’s parameters, Bete was able to calculate how much gas cooling was possible. The gas cooling was estimated to be about 5°F (2°C) if 4.25 gpm (16 L/min) is evaporated. The customer estimated the oil temperature would decrease as much as 16°F (9°C). Because a very small drop size was needed, Twenty-one (21) ¼” PJ10 misting nozzles were used for each of the three fans. Only two fans will be operated at a time, needing 42 of the Bete ¼” PJ10 misting nozzles at 2900 psi (200 bar), to reach the estimated 4.5 gpm (16.7 L/min) to be evaporated.

Custom Spray Nozzle Solutions – Gas Turbine Cooling Drawings and Sketches: