Custom Spray Nozzle Solutions – Pharmaceutical Spray Drying

Application #051180

Industry: Pharmaceutical

Application: Spray Drying

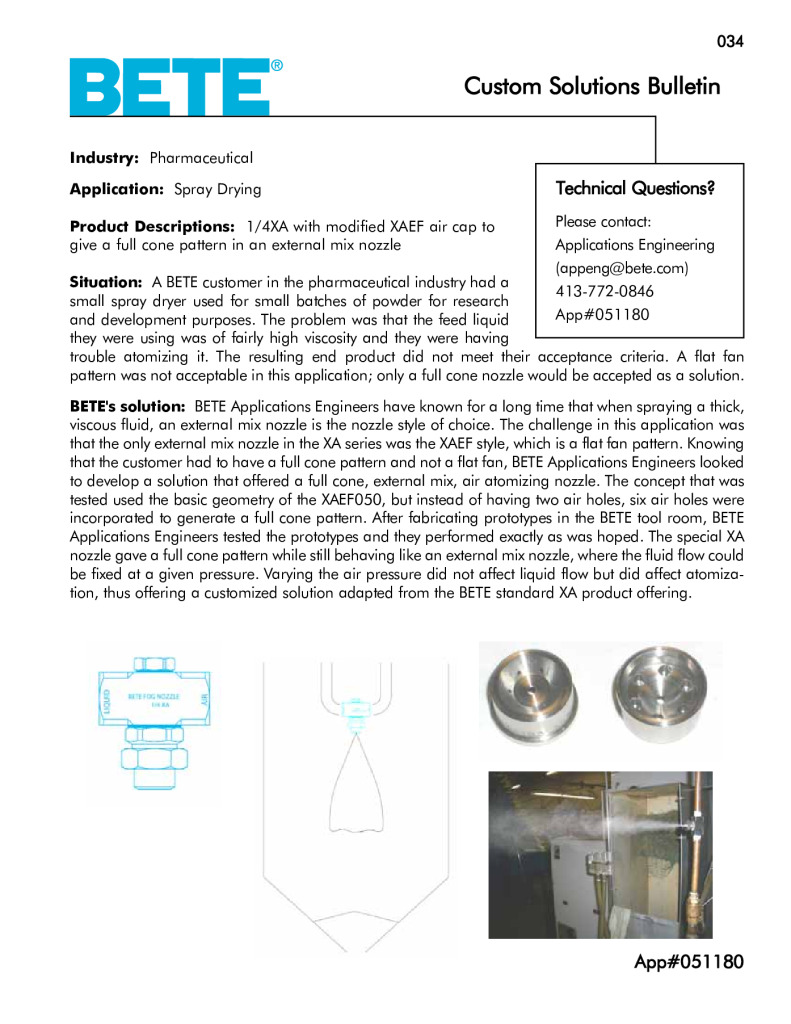

Product Description: 1/4 XA with modified Bete XAEF air cap to give a full cone pattern in an external mix nozzle

Situation: A Bete customer in the pharmaceutical industry had a small spray dryer used for small batches of powder for research and development purposes. The problem was that the feed liquid they were using was of fairly high viscosity and they were having trouble atomizing it. The resulting end product did not meet their acceptance criteria. A flat fan pattern was not acceptable in this application; only a full cone nozzle would be accepted as a solution.

Solution: Bete Applications Engineers have known for a long time that when spraying a thick, viscous fluid, an external mix nozzle is the nozzle style of choice. The challenge in this application was that the only external mix nozzle in the XA series was the XAEF style, which is a flat fan pattern. Knowing that the customer had to have a full cone pattern, and not a flat fan, Bete Applications Engineers looked to develop a solution that offered a full cone, external mix, air atomizing nozzle. The concept that was tested used the basic geometry of the XAEF050, but instead of having two air holes, six air holes were incorporated to generate a full cone pattern. After fabricating prototypes in the Bete tool room, Bete Applications Engineers tested the prototypes and they performed exactly as was hoped. The special XA nozzle gave a full cone pattern while still behaving like an external mix nozzle, where the fluid flow could be fixed at a given pressure. Varying the air pressure did not affect liquid flow but did affect atomization, thus offering a customized solution adapted from the Bete standard XA product offering.

Custom Spray Nozzle Solutions – Pharmaceutical Spray Drying Drawings and Sketches: