Custom Spray Nozzle Solutions – Petroleum Processing Material Injection

Application #051093

Industry: Petroleum Processing

Application: Material Injection

Product Description: Special Adapter

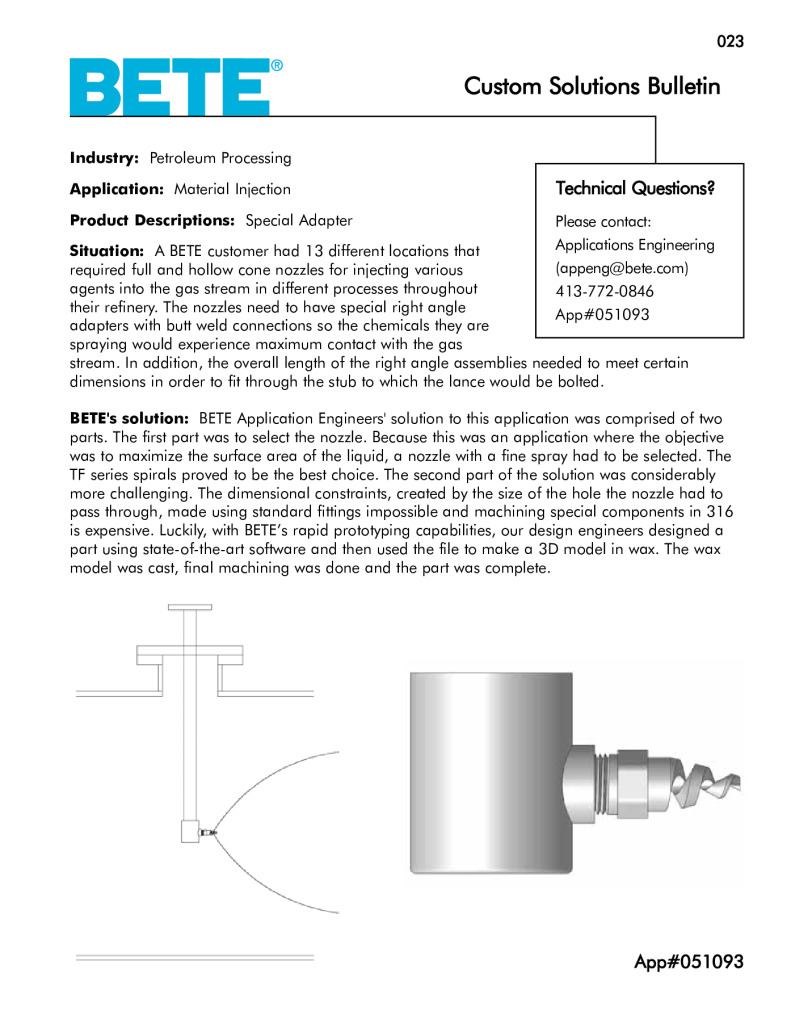

Situation: A Bete customer had 13 different locations that required full and hollow cone nozzles for injecting various agents into the gas stream in different processes throughout their refinery. The nozzles needed to have special right angle adapters with butt weld connections so the chemicals they are spraying would experience maximum contact with the gas stream. In addition, the overall length of the right angle assemblies needed to meet certain dimensions in order to fit through the stub to which the lance would be bolted.

Solution: Bete Application Engineers’ solution to this application was comprised of two parts. The first part was to select the nozzle. Because this was an application where the objective was to maximize the surface area of the liquid, a nozzle with a fine spray had to be selected. The TF series spirals proved to be the best choice. The second part of the solution was considerably more challenging. The dimensional constraints, created by the size of the hole the nozzle had to pass through, made using standard fittings impossible and machining special components in 316 is expensive. Luckily, with Bete’s rapid prototyping capabilities, their design engineers designed a part using state-of-the-art software and then used the file to make a 3D model in wax. The wax model was cast, final machining was done and the part was complete.

Custom Spray Nozzle Solutions – Petroleum Processing Material Injection Drawings and Sketches: