Custom Spray Nozzle Solutions – Heavy Vacuum Gas Sprayer

Application #081427

Industry: Petroleum Processing

Application: Material Injection

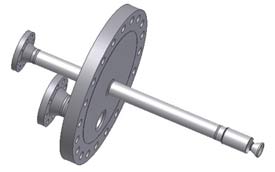

Product Description: Bete MaxiPass Lance with Port for Temperature Sensor

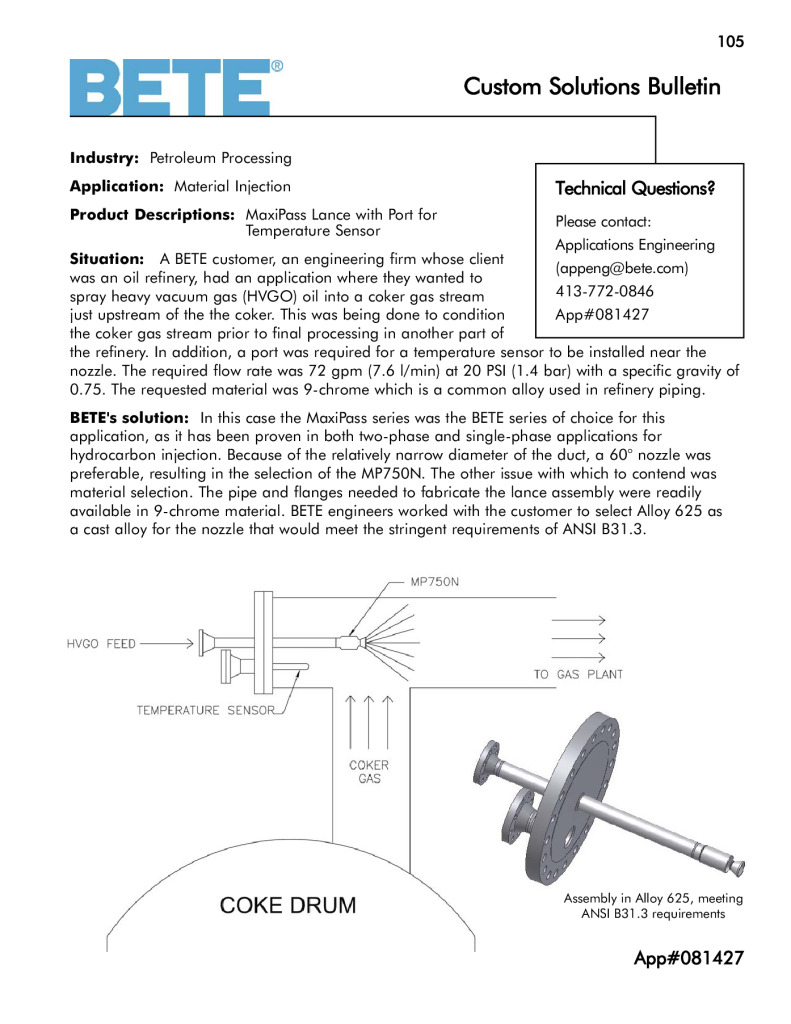

Situation: A Bete customer, an engineering firm whose client was an oil refinery, had an application where they wanted to spray heavy vacuum gas (HVGO) oil into a coker gas stream just upstream of the the coker. This was being done to condition the coker gas stream prior to final processing in another part of the refinery. In addition, a port was required for a temperature sensor to be installed near the nozzle. The required flow rate was 72 gpm (7.6 l/min) at 20 PSI (1.4 bar) with a specific gravity of 0.75. The requested material was 9-chrome which is a common alloy used in refinery piping.

Solution: In this case the MaxiPass series was Bete’s series of choice for this application, as it has been proven in both two-phase and single-phase applications for hydrocarbon injection. Because of the relatively narrow diameter of the duct, a 60° nozzle was preferable, resulting in the selection of the MP750N. The other issue with which to contend was material selection. The pipe and flanges needed to fabricate the lance assembly were readily available in 9-chrome material. Bete engineers worked with the customer to select Alloy 625 as a cast alloy for the nozzle that would meet the stringent requirements of ANSI B31.3.

Custom Spray Nozzle Solutions – Heavy Vacuum Gas Sprayer Drawings and Sketches: