Custom Spray Nozzle Solutions – Spray Drying in Food Processing

Application #081116

Industry: Food Processing

Application: Spray Drying

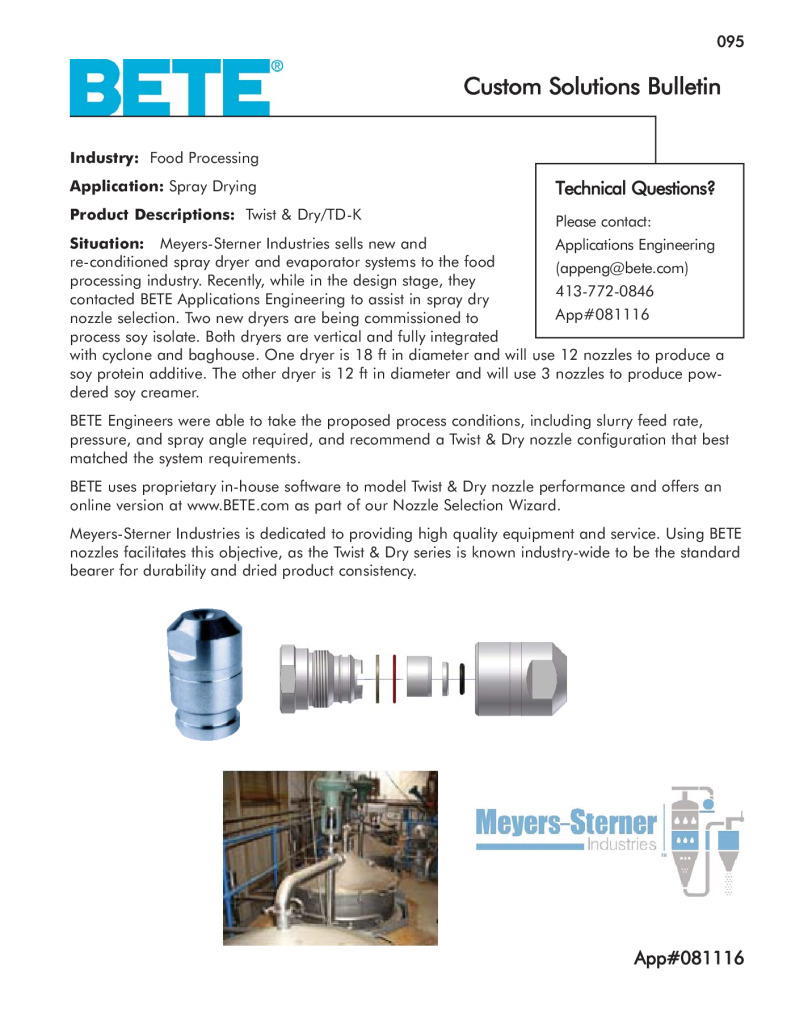

Product Description: Bete Twist & Dry / TD-K

Situation: Meyers-Sterner Industries sells new and re-conditioned spray dryer and evaporator systems to the food processing industry. Recently, while in the design stage, they contacted Bete Applications Engineering to assist in spray dry nozzle selection. Two new dryers are being commissioned to process soy isolate. Both dryers are vertical and fully integrated with cyclone and baghouse. One dryer is 18 ft in diameter and will use 12 nozzles to produce a soy protein additive. The other dryer is 12 ft in diameter and will use 3 nozzles to produce powdered soy creamer.

Solution: Bete Engineers were able to take the proposed process conditions, including slurry feed rate, pressure, and spray angle required, and recommend a Twist & Dry nozzle configuration that best matched the system requirements. Bete uses proprietary in-house software to model Twist & Dry nozzle performance. Meyers-Sterner Industries is dedicated to providing high quality equipment and service. Using Bete nozzles facilitates this objective, as the Twist & Dry series is known industry-wide to be the standard bearer for durability and dried product consistency.

Custom Spray Nozzle Solutions – Spray Drying in Food Processing Drawings and Sketches: