Custom Spray Nozzle Solutions – Dust Control in Limestone Slurry Tank

Application #051356

Industry: Electric Utilities

Application: Dust Control

Product Description: Right angle adapter for Bete XA extension

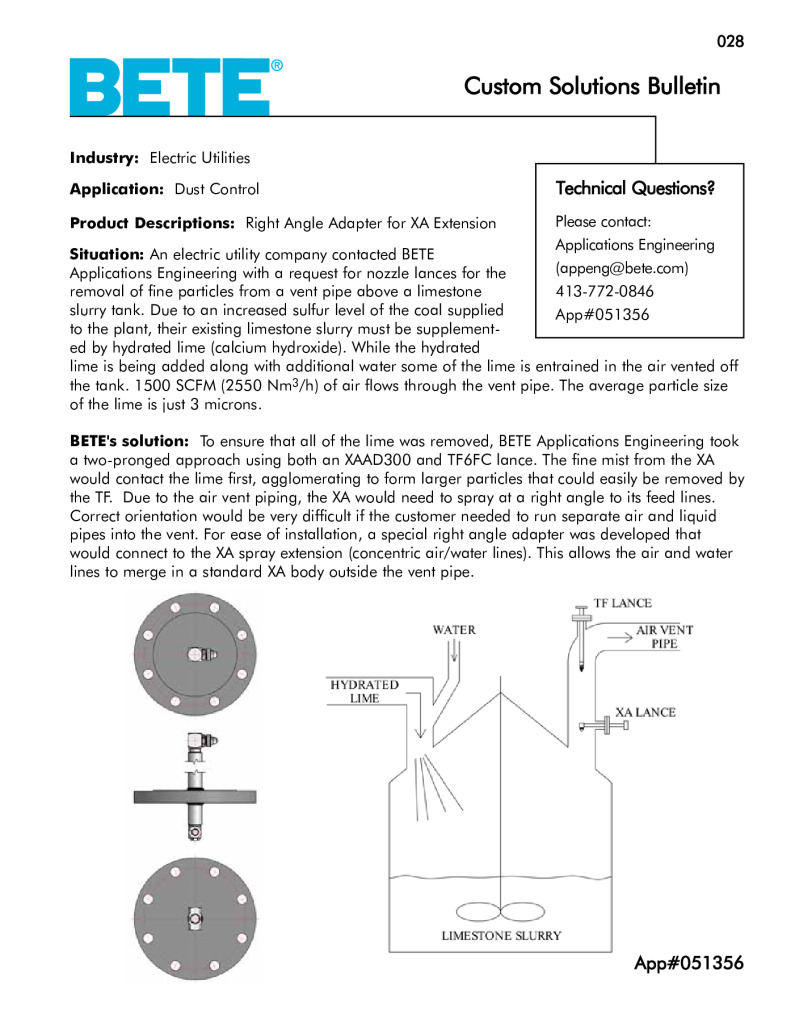

Situation: An electric utility company contacted Bete Applications Engineering with a request for nozzle lances for the removal of fine particles from a vent pipe above a limestone slurry tank. Due to an increased sulfur level of the coal supplied to the plant, their existing limestone slurry must be supplemented by hydrated lime (calcium hydroxide). While the hydrated lime is being added along with additional water some of the lime is entrained in the air vented off the tank. 1500 SCFM (2550 Nm³/h) of air flows through the vent pipe. The average particle size of the lime is just 3 microns.

Solution: To ensure that all of the lime was removed, Bete Applications Engineering took a two-pronged approach using both an XAAD300 and TF6FC lance. The fine mist from the Bete XA would contact the lime first, agglomerating to form larger particles that could easily be removed by the Bete TF. Due to the air vent piping, the XA would need to spray at a right angle to its feed lines. Correct orientation would be very difficult if the customer needed to run separate air and liquid pipes into the vent. For ease of installation, a special right angle adapter was developed that would connect to the XA spray extension (concentric air/water lines). This allows the air and water lines to merge in a standard XA body outside the vent pipe.

Custom Spray Nozzle Solutions – Dust Control in Limestone Slurry Tank Drawings and Sketches: