Custom Spray Nozzle Solutions – Gas Cooling

Application #091358

Industry: Chemical Processing

Application: Gas Cooling

Product Description: Custom Bete XAPR Spray Lance Design

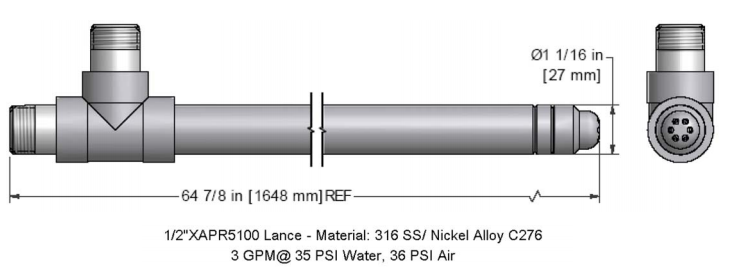

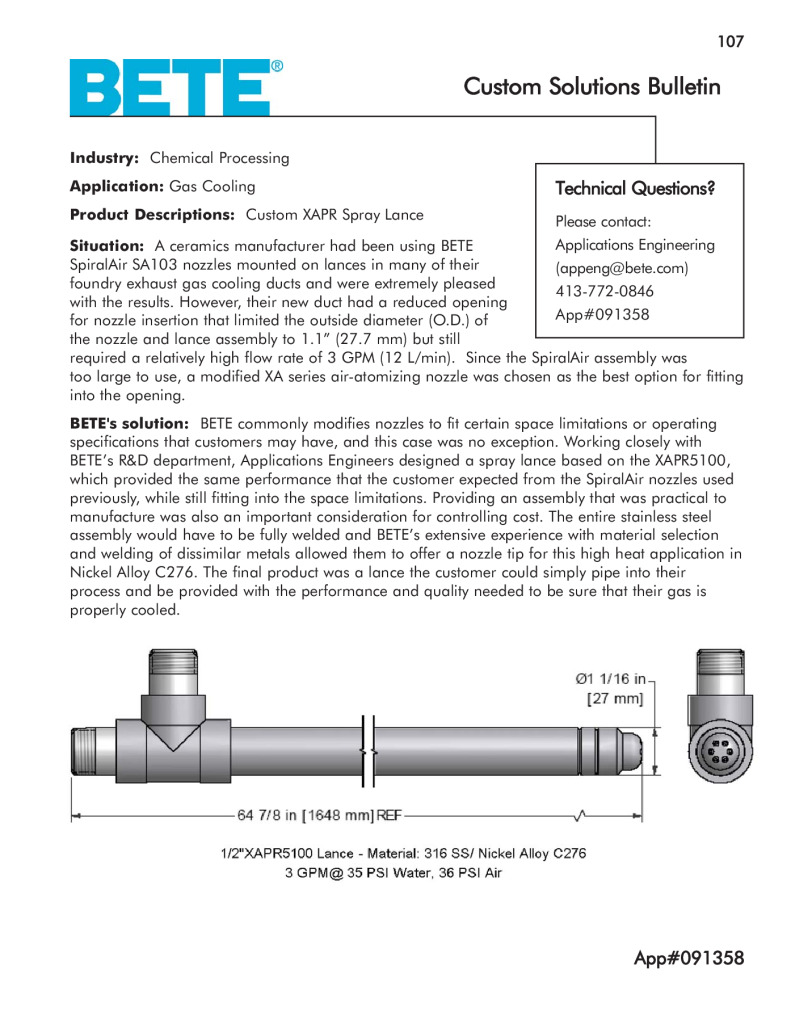

Situation: A ceramics manufacturer had been using Bete SpiralAir SA103 nozzles mounted on lances in many of their foundry exhaust gas cooling ducts and were extremely pleased with the results. However, their new duct had a reduced opening for nozzle insertion that limited the outside diameter (O.D.) of the nozzle and spray lance assembly to 1.1″ (27.7 mm) but still required a relatively high flow rate of 3 GPM (12 L/min). Since the SpiralAir assembly was too large to use, a modified Bete XA series air-atomizing nozzle was chosen as the best option for fitting into the opening.

Solution: Bete commonly modifies nozzles to fit certain space limitations or operating specifications that customers may have, and this case was no exception. Working closely with Bete’s R&D department, Bete Applications Engineers designed a spray lance based on the XAPR 5100, which provided the same performance that the customer expected from the SpiralAir nozzles used previously, while still fitting into the space limitations. Providing an assembly that was practical to manufacture was also an important consideration for controlling cost. The entire stainless steel assembly would have to be fully welded and Bete’s extensive experience with material selection and welding of dissimilar metals allowed them to offer a nozzle tip for this high heat application in Nickel Alloy C276. The final product was a spray lance the customer could simply pipe into their process and be provided with the performance and quality needed to be sure that their gas is properly cooled.

Custom Spray Nozzle Solutions – Gas Cooling Drawings and Sketches: