Custom Spray Nozzle Solutions – Ethanol Area Distribution

Application #051931

Industry: Chemical Processing

Application: Area Distribution

Product Description: Distribution Design

Situation: A Bete customer was designing a bio-diesel reactor (a device which produces a diesel-like fuel from vegetable oil and greases) in which he wanted to gently spread ethanol over the surface of the vegetable oil in formulation process, but didn’t want the spray of the ethanol to stir up the surface of the oil.

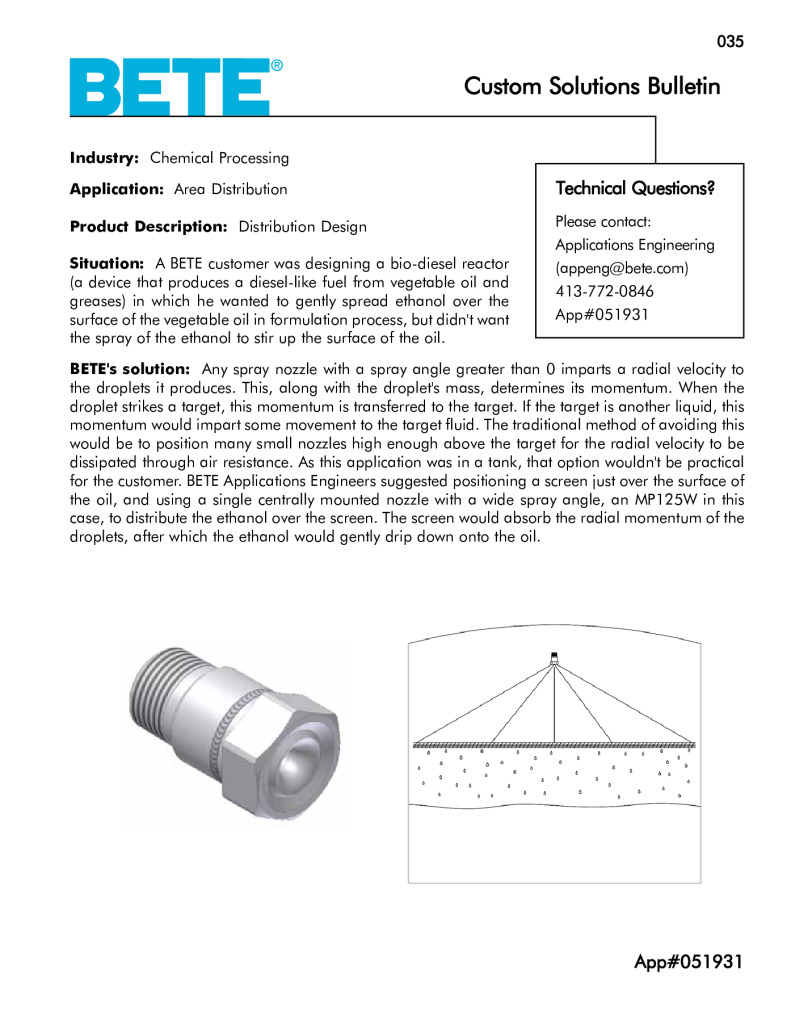

Solution: Any spray nozzle with a spray angle greater than 0 imparts a radial velocity to the droplets it produces. This, along with the droplet’s mass, determines its momentum. When the droplet strikes a target, this momentum is transferred to the target. If the target is another liquid, this momentum would impart some movement to the target fluid. The traditional method of avoiding this would be to position many small nozzles high enough above the target for the radial velocity to be dissipated through air resistance. As this application was in a tank, that option wouldn’t be practical for the customer. Bete Applications Engineers suggested positioning a screen just over the surface of the oil, and using a single centrally mounted nozzle with a wide spray angle, an MP125W in this case, to distribute the ethanol over the screen. The screen would absorb the radial momentum of the droplets, after which the ethanol would gently drip down onto the oil.

Custom Spray Nozzle Solutions – Ethanol Area Distribution Drawings and Sketches: