Industrial Tank Cleaning Machine that Fits Through Standard 2 in. Inlets

Originally developed to clean fuel storage tanks, the Alfa Laval GJ 9.2 is ideal for any industrial tank less than 1250 gallons. Designed to fit through standard 2 inch inlets, the device’s powerful rotary jets blast away contaminants, and breaks up the most challenging of residues.

For Diesel Fuel Tanks: Diesel fuel can run right through the GJ 9.2, as a cleaning agent, which saves not only on time, but mitigates contamination concerns and waste disposal.

Benefits:

- Fits through a 2 in. (50 mm) opening

- Cleans standard ASTs up to 1,250 gallons (4,750 l) in capacity

- Powerful: 7 lbs (3 kg) of cleaning force at 5 ft. (1.5 m)

- Operates at lower pressures

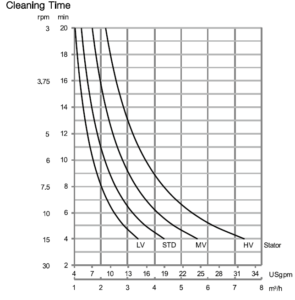

Operating Range:

- Pressure: 50 to 100+ psi (4 to 7+ bar)

- Temperature: 32° to 200°F (0° to 95°C)

- Flow Rate: 6 to 20 gpm (23 to 76 l/min)

- Cleaning Radius: 10 ft. (3 m)

- Wash Cycle Time: 4 to 20 min.

- Impact: 7 lbs (3 kg) at 5 ft. (1.5 m)

Overall Dimensions:

- Height: 20 in. (508 mm)

- Body Diameter: 1.9 in. (48 mm)

- Weight: 5.5 lb (2.5 kg)

- Clearance: 2 in. (51 mm) minimum passageway I.D.

This is also a fuel polishing machine, however GASOLINE CANNOT be run through this machine. Most other fuel types are acceptable, especially diesel.

|

|

|

|

|

|

Specifications:

| Inlet Connection: | 3/4 in. NPT Female | 3/4 in. BSP Female |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the rotor shaft is plasma-sprayed with a Chromium Oxide coating on stainless steel. |

| Shaft & Gearbox Bushings: | Turbine shaft thrust is absorbed by a Tungsten carbide bushing. Gear bushings are carbon filled polyphenylene sulfide. |

| Static Seals: | O-Ring materials are selected for each application. Viton is standard, with Kalrez available. Other materials can be supplied on special order. |

| Dynamic Seals and Bearings: | Rotary shaft and housing seals/bearings are made from carbon-filled-reinforced polyphenylene sulfide for extra long wear and protection against leakage, abrasion and deposit build-up. |

| Nozzles: | Dual or quad Nozzle sizes from 0.1 in. (2.5 mm) to 0.2 in. (5 mm) |

| Drive Mechanism: | The wash fluid enters the GJ 9.2 at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the drive or rotor shaft. The bottom of this shaft is connected to the inside of a sealed, robust planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The sealed planetary gearhead has an external casing made of steel, surface-anodized to become stainless. This sealed gearhead is located inside the gearbox, which itself is sealed, and thus does not require any lubricant. All internal gearhead parts are hardened sintered steel. |

| Lubricant: | A food grade lubricant is inside the sealed gearhead casing. |