John Brooks Chemical Metering Pump System that is Precise, Cost-Effective and Safe

The Challenge

The chemical metering pump system of a well-reputed company in the Waste Water Management sector was faced with the challenge of decreasing accuracy, increased inefficiency and increased cost, from their water treatment system that used Air Operated Double Diaphragm (AODD) pumps for metering some of their chemical treatments.

Pulsations from the reciprocating action of the AODD pumps were an issue, and the pumps were unable to accurately control the flow-rate of the chemicals being injected into the water, leading to more than necessary use of chemicals in their process and adverse effect on the quality of treated water.

Our Solution

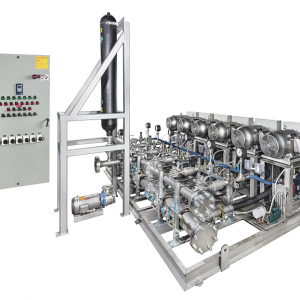

We replaced the old AODD pumps in the existing system with a prepackaged pump skid system, that included Seepex progressive cavity metering pumps, that are non – pulsing and have a linear flow. Seepex pumps are perfectly suited for chemical dosing because of their easy calibration and maintenance, “no vapor locking” design and their ability to handle high viscosity and corrosive chemicals.

Our pump skid design included three Seepex MD012-12 progressive Cavity Pumps with CPVC housing and Hastelloy C internals, custom mechanical seals so the pumps could be mounted vertically, three calibration columns, three relief valves, ball valves, drain valves and associated Sch 80 CPVC tubing.

We were therefore able to provide the customer a well-engineered, pre-packaged system that was the perfect solution to their problem and which is now an important and integral part of their water treatment process.

Application Conditions

- 2 units pumping Biocide at flow rates of 0.005 – 1.36 m3/h

- 1-unit pumping Scale Inhibitor at a flow rate of 0.005 – 1.36 m3/h

Value from switching to John Brooks Chemical Metering Pump System

- Lower chemical costs

- Consistent water quality

- Substantially reduced equipment maintenance resulting in lower costs

- Elimination of excessive operator involvement

- Lessened damage to the process due to the elimination of pulsing in the chemical lines

Call 1-877-624-5757 to talk to our chemical metering pump system representative.

More Systems from John Brooks Company

John Brooks Chemical Additive Facility

Complete Packaged Chemical Additive Facility 2 stacked 40’ sea containers with Chemical...

High Pressure Wash Systems from John Brooks Company Limited

Customized systems that run efficiently to save you money, now and in...

Filtration Systems from John Brooks Company

Filtration Systems custom designed for your unique applications Here are some of...

Gorman-Rupp Lift Stations

Gorman-Rupp ReliaSource® above-ground pump stations are 100% custom-engineered, manufactured, assembled and pretested...

Fuel Oil Systems from John Brooks Company

Fuel Oil Systems custom designed for your unique application Here is an example...

High Pressure Rinsing Systems from John Brooks

High Pressure Rinsing Systems from John Brooks Company Limited High Pressure Rinsing...

Gas Cooling Systems from John Brooks Company

Gas Cooling Systems for Emergency Shutdown Procedures at an Oil Refinery This...

Injection Lances and Quills

Custom Injection Lances and Quills, Chemical Injectors and Spray Lances Injection Lances and...

Pump Filter Packaged Systems

John Brooks Filter & Pump Packaged Systems are designed to save you...

Portable Pumping Systems from John Brooks

Portable Pumping System on a Towable Highway Rated Trailer This portable pumping...

Pressure Booster Systems from John Brooks Company

Pressure Booster Systems custom designed for your unique application Here are some of...

John Brooks Automated Retractable Nozzle System

The Automated Retractable Nozzle System designed by John Brooks Company Limited injects...

Submersible Sewage Pumping Systems

Submersible Sewage Pumping Systems from John Brooks Company Limited Packaged submersible sewage...