EATON Filtration Products including Automatic Self Cleaning Filtration Products and Manual Pipeline Strainers for protecting process system components from damaging pipeline debris and Gas Liquid Separation which will remove +99% of all damage causing moisture and solid particles 10 microns and larger.

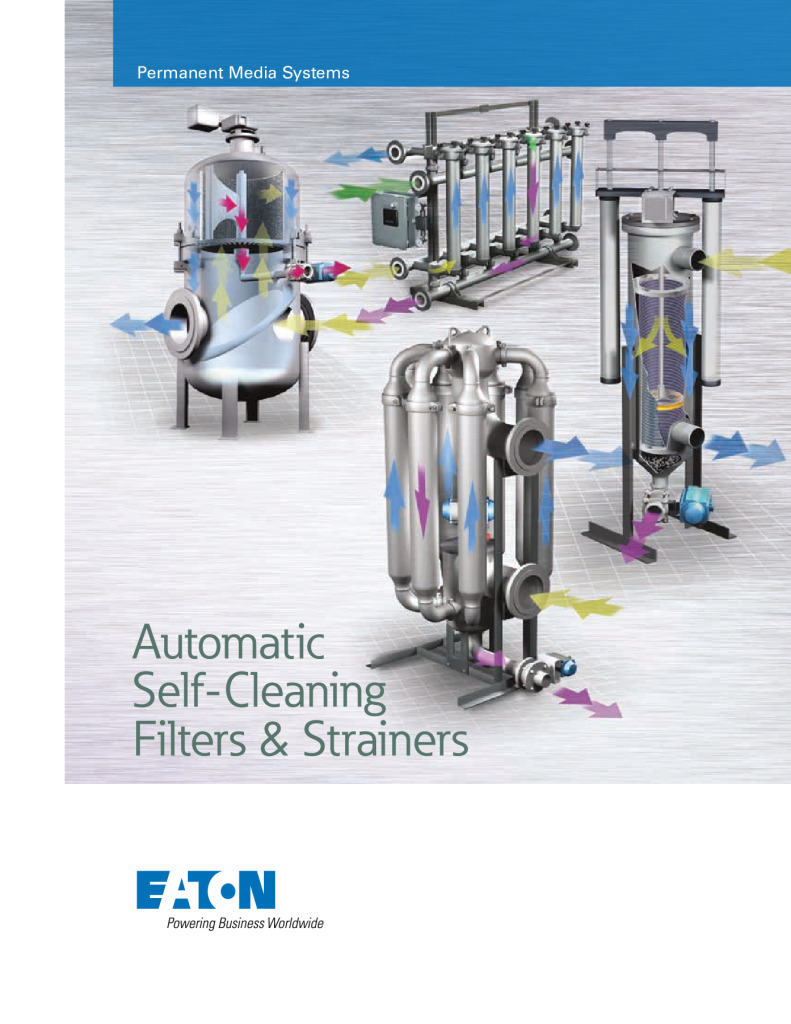

EATON Automatic Self Cleaning Filtration

Automatic Self Cleaning Filters and Industrial Strainers assure continuous flow, simplified maintenance and worry-free operation. The self cleaning product line includes tubular backwashing and mechanically cleaned technology. Eaton’s Model 2596 self cleaning strainer is available in custom designs and exotic materials upon request.

|

Mechanically Cleaned FiltersEaton’s range of automatic self-cleaning filters, dramatically reduce product loss, require minimal operator intervention and improve flow consistency. The MCF features the fastest cleaning action of the mechanically cleaned family. The DCF Series operates at a consistently low differential pressure and delivers simple, reliable operation in which a low initial investment is a key driving factor. |

|

Tubular Backwashing FiltersMatching media configuration, retention, and materials to your application is easy when you select an Eaton backwashing/tubular filtration system. We offer media choices from compact configurations that pack a large amount of surface area into a small amount of space, to simple strainer-type systems for removing larger contaminants. |

|

High Flow Mechanically Cleaned StrainersThis new strainer design offers minimal purge volumes in fresh water applications, allowing you to save on the cost of make up liquids, chemical treatment and heating energy. |

|

Model 2596 Cast and Fabricated Pipeline StrainersThe Eaton automatic self-cleaning industrial strainer is a motorized strainer designed for the continuous removal of entrained solids from liquids in pipeline systems. It has successfully performed in industrial, process, water, wastewater, power, paper and municipal applications for over 30 years. |

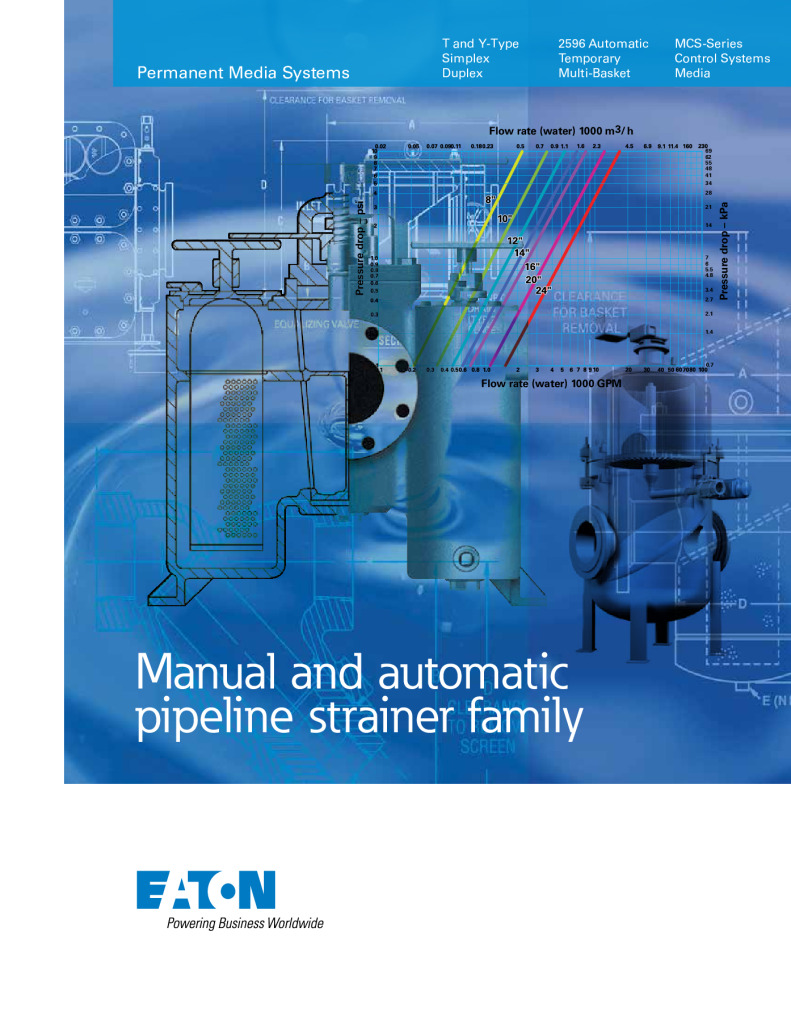

Manual Pipeline Strainers

Eaton’s Manual Strainers are used by industrial and commercial customers to protect their process piping equipment by removing debris from the liquid that flows through pipelines. Products include duplex basket strainers, simplex basket strainers, Y strainers and Tee type strainers. Eaton offers pipeline basket strainers in sizes from ¼” to 48”. Our Models 73, 72 and 53BTX strainers are American Bureau of Shipping (ABS) Type Approved for ship designers, builders and owners.

|

Simplex Industrial Basket StrainersA simplex basket strainer is used where the line can be shut down for short periods to clean or change baskets. It becomes an integral part of the pipeline and all flow passes through it. |

|

Duplex Industrial Basket StrainersA duplex basket strainer can operate continuously and never has to be shut down for cleaning. A diverter plug is carefully fitted to the strainer body. It permits flow to pass either left or right. When one basket becomes full, the flow is shifted to the other one. |

|

Y-Strainers (Wye Strainers)Eaton Y (Wye) strainers are a cost-effective solution for the mechanical removal of unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. |

|

Fabricated StrainersEaton offers several models of fabricated strainers for coarse filtration that include the simplex strainer, the duplex strainer, the cone strainer, and tee type designs of fabricated strainers. |

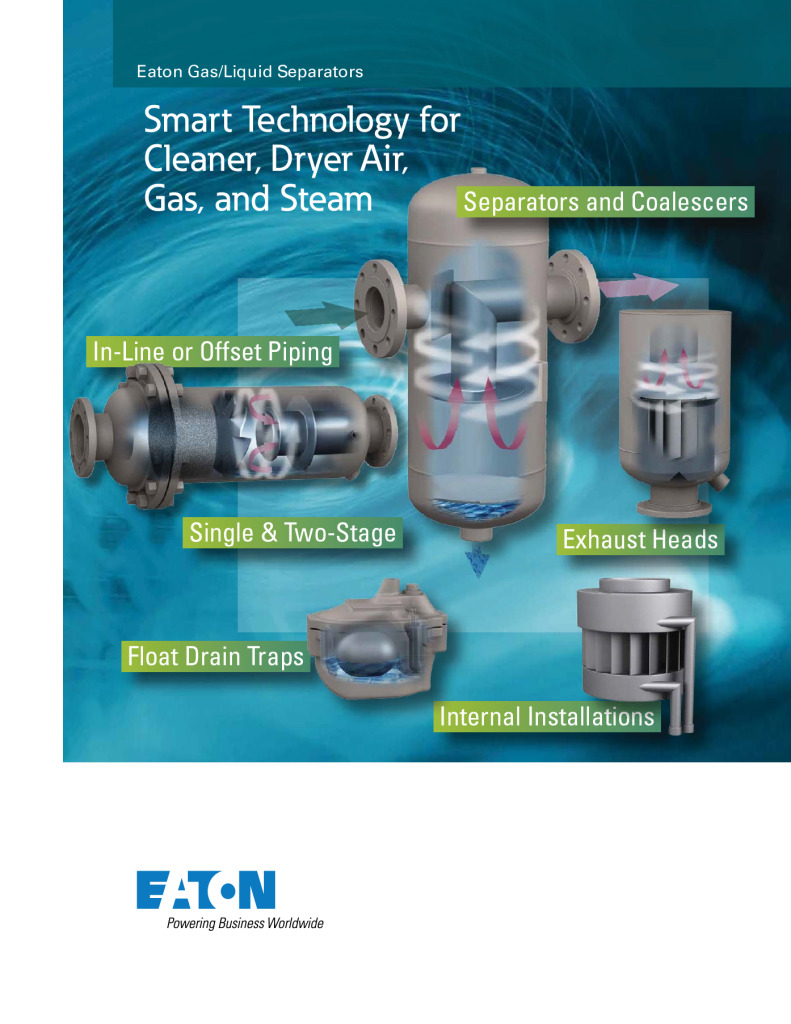

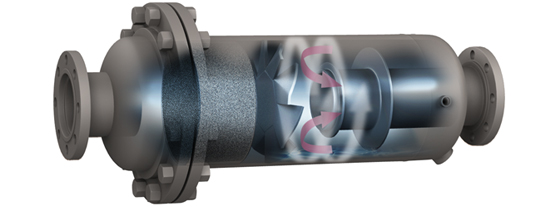

EATON Gas Liquid Separation

Eaton Gas Liquid Separators remove up to 99% of all damage causing moisture and solid particles larger than 10 microns.

Typically installed following an intercooler or aftercooler, the separators are used to remove entrained moisture that would otherwise cause damage in successive stages of compression or to subsequent processes. They’re ideal for entrainment removal in primary air lines leading to air-using equipment such as air chucks, air nozzles, and paint spray equipment.

Separators are often installed ahead of steam turbines to protect the turbine blades from the erosive action of wet steam, pipe scale, and other damage-causing entrained solids. They’re also installed in steam distribution lines to assure clean, dry steam enters heat exchangers, pressure reducing valves, temperature regulators, meters, and other process equipment.

|

In-line SeparatorsEaton in-line gas/liquid separators are compact, easy to install and can are supported by the pipeline. |

|

Separator Exhaust HeadsEaton Exhaust Heads are designed to separate entrained water and oil from exhaust air, gas or steam prior to being discharged directly into the atmosphere. |

|

Coalescers SeparatorsThe Coalescer Separator’s unique two-stage design removes up to 99% of all liquid and solid particles larger than 4 microns in size. |

|

Internal SeparatorsDesigned for installation inside receivers, steam drums, and other vessels, Eaton internal gas liquid separators remove up to 99% of particles and liquid droplets 10 microns or larger from air, gas, or steam. |

|

Two-Stage SeparatorsEaton two-stage gas/liquid separators are for applications requiring extremely fine entrainment removal. The first stage is a centrifugal separator that removes slugs and heavy liquid loads. The second stage uses coalescing filters to remove nearly all remaining droplets plus particles as small as 0.3 microns from air, gas and steam processes. |

|

Separator Drain TrapsEaton Float Drain Traps are available in a variety of models and materials of construction, featuring the Model 90-AC, Model 95-AC, Model 230-AC and Model 350-AC. |

|

Dry Type SeparatorsEaton Dry Type Gas/Liquid Separators have been designed for applications with a higher than normal load of entrained solids. |