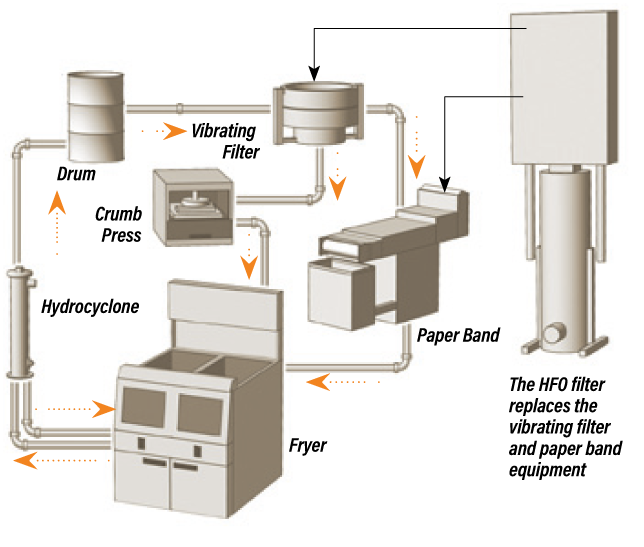

Eaton Hot Fry Oil Filters are mechanically cleaned filters for commercial cooking oil recycling – replacing the vibrating filter and paper band equipment. Temperature maximum 400° F (204° C).

Eaton Hot Fry Oil Filters – Basic Fry Oil Process

|

EATON Hot Fry Oil Filters – Specifications

Specifications |

|

|---|---|

| Total Volumetric Capacity | 11 gal | 41.6 liters |

| Purge Chamber Capacity | 1.5 gal | 6 liters |

| Filtration Surface Area | 610 in² | 3935 cm² |

| Flow Rate Range at 100μ | 30 – 200 gpm | 6.8-45.4 m³/hr |

| Maximum Temperature | 400° F | 204° C |

| Maximum Pressure | 150 psi | 10 bar |

| Minimum Pressure | 30 psi | 2 bar |

| Single Unit Weight | 250 lbs | 113.4 kg |

| Air Requirement | 80 psi to 120 psi | 5.5 to 8.2 bar – 5.5 cfm |

EATON Hot Fry Oil Filters Features

- Reduced Fire Hazard

- Improved Personnel Safety

- Lower Maintenance

- Tighter Retention Capability

- No Consumable Media

- FDA Compliant Materials

- Environmentally Friendly Design

- Produces Lower Volume of Waste

Powered by DCF Self Cleaning Technology

- High turn-over rates result in improved quality

- Reduced oxidation rates of non-hydrogenated oil

- Tighter filter retentions optimize crumb removal

- Closed system reduces employee exposure

- Eliminates costs associated with consumable media

- Environmentally friendly design reduces disposal costs

- Unique leak containment system

How the Self-Cleaning Hot Fry Oil Filter Works:

- The unfiltered oil flows in the top filter inlet and passes from the inside to the outside of the 316 stainless steel slotted filter media.

- The unwanted solids are retained on the inside of the screen, and the filtered oil exits the filter through the bottom outlet and goes to the process.

- A spring loaded cleaning disc periodically wipes the internal surface of the filter media, removing the collected debris and directing it to the bottom chamber out of the flow path.

- The idea is to wipe the filter media as often as necessary to maintain a very low, constant, clean differential pressure across the system.

- The collected debris is automatically purged from the filter — using system pressure — in .7 seconds.

- Typically, the purge function takes place every 1 – 4 hours depending on the amount of collected debris.