EATON DCF 1600 Mechanically Cleaned Filters are ideal for highly viscous, abrasive, or sticky liquids. Eaton DCF 1600 mechanically cleaned filters operate at a consistently low differential pressure and deliver simple, reliable operation in which a low initial investment is a key driving factor.

EATON DCF 1600 Feature Comparison Chart

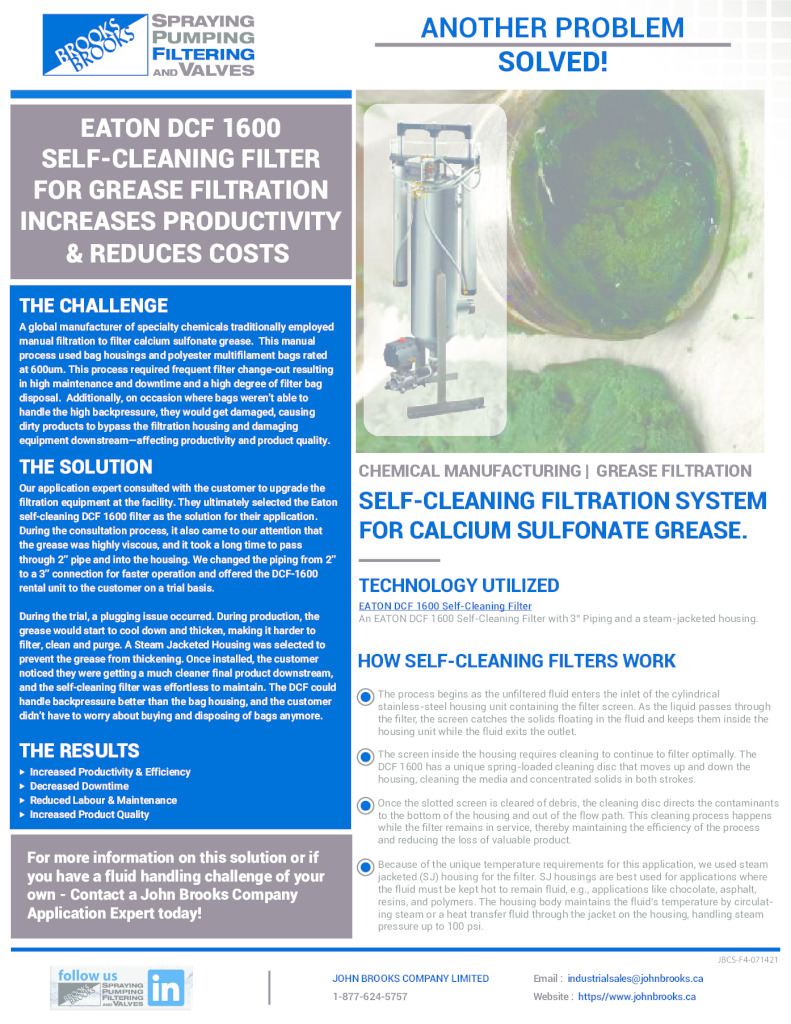

| FEATURES | DCF-400 | DCF-800 | DCF-1600 |

|---|---|---|---|

| Single Unit Weight | 35 lbs | 16 kg | 75 lbs | 34 kg | 215 lbs | 97.5 kg |

| Service Height | 61.25 in | 1556 mm | 69.25 in | 1760 mm | 102 in | 2591 mm |

| Total Volumetric Capacity | 0.94 gal | 3.5 liters | 3.9 gal | 14.8 liters | 11 gal | 41.6 liters |

| Purge Chamber Capacity | 4 fl. oz | 119 ml | 25 fl. oz | 0.74 liters | 1.5 gal | 6 liters |

| Filtration Surface Area | 112 in² | 722 cm² | 264 in² | 1703 cm² | 610 in² | 3935 cm² |

| Flow Rate Range at 100μ | 2–20 gpm | 0.45–4.5 m3/hr | 20–60 gpm | 4.5–13.6 m3/hr | 60–200 gpm | 13.6–45.4 m3/hr |

| Maximum Temperature* | 350˚ F | 177˚ C | 350˚ F | 177˚ C | 350˚ F | (177˚ C |

| Maximum Pressure | 300 psi | 21 bar | 150 psi (10.5 bar) standard | 150 psi (10.5 bar) standard |

| Service Requirements Minimum Air for Actuator Drive |

60 psi at 5 cfm | 4 bar @ 8.5 m3/min | 60 psi at 5 cfm | 4 bar @ 8.5 m3/min | 80 psi at 5 cfm | 5 bar @ 8.5 m3/min |

| Electrical for Controllers | Automated only Models – 110/220V, 50/60 Hz, single phase | ||

* Dependent on elastomer seal selection.

Features of EATON DCF 1600 Mechanically Cleaned Filters

- Automation Minimizes Disposable Waste and Labor Costs

- Elimination or reduction in disposable filter bags and cartridges for reduced operator handling inventory costs and landfill waste

- Reduction in product loss, more thorough contaminant purge in a highly concentrated waste stream

- Virtually maintenance free, near 100% uptime

- Compact design, lower capital cost to fit most installations

- Stainless steel screens from 15 micron slots to 1/4″ perforations to handle a wide range of filtration needs

- Available with UHMWPE, Urethane-, Teflon, or Kynar-Cleaning Discs

The DCF is the best self-cleaning filtration solution for minimizing product loss in high-value and/or high viscosity fluids.

When processing water and water-like liquids where a low initial investment is demanded, DCF single actuator models deliver tremendous benefits. Available in 400, 800, and 1600 sizes, The DCF-Series enables operation at a vast range of flow rates and retentions.

The DCF-800 and DCF-1600 are also available in twin actuator models, which are designed for the rigors of processing highly viscous, abrasive, sticky, or otherwise hard-to-process liquids. DCF Filters are suitable for a broad spectrum of challenging applications and accommodate a wide range of flow and retention requirements.

A unique circular cleaning disc design (MCF) ensures intimate contact with the screen to thoroughly and uniformly clean the media.

Markets Served:

- Chemicals

- Ethanol

- Food and Beverage

- Manufacturing

- Oil and Gas

- Pulp and Paper

- PetroChem

- Pharmaceuticals

- Water

Typical Applications

- Adhesives

- Chocolate

- CIP Fluids (Sodium Hydroxide)

- Curtain Coaters

- Detergents

- Edible Oils

- Ethanol Processing

- Hot Fry Oils

- Ink

- Lime Slurries

- Machining Coolants

- Nutricuticals

- PCC/GCC Slurries

- Paint

- Paper Coatings

- Petroleum Based Greases

- Phenolic Resins

- Starch

- Tallow