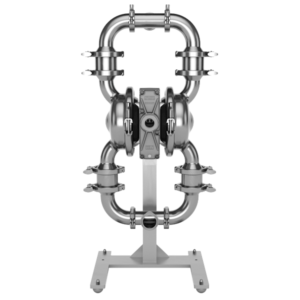

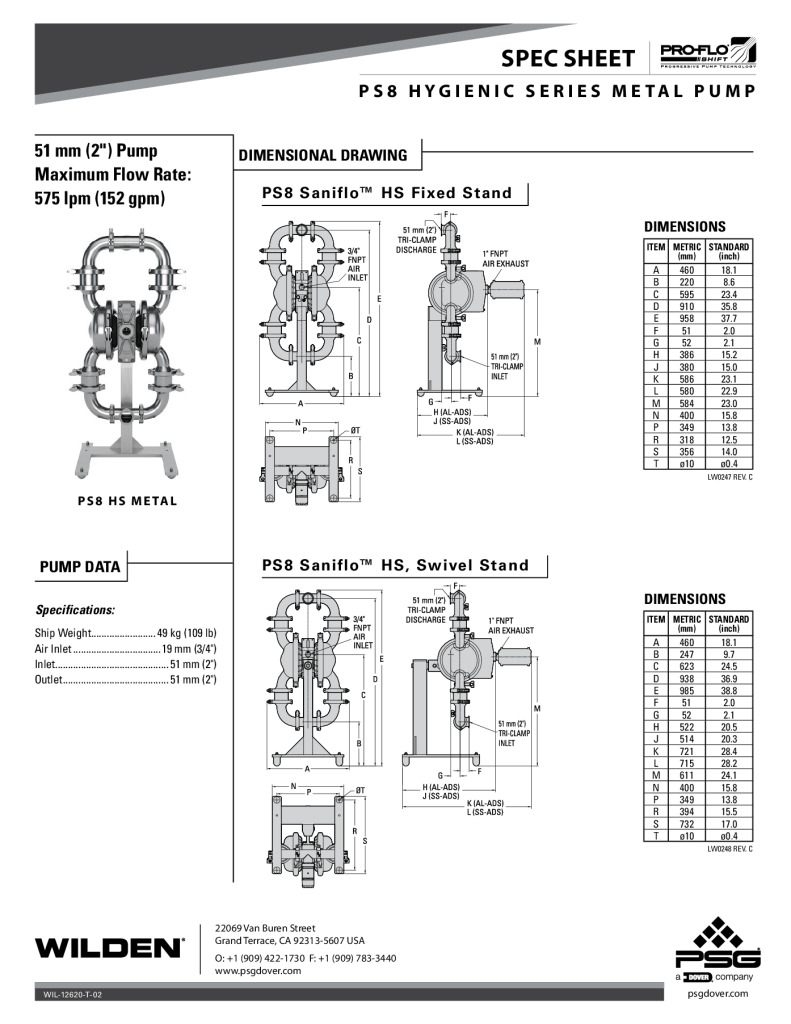

2″ | 51 mm Saniflo Hygienic Pro-Flo SHIFT Series Clamped Metal Pump

Wilden PS8 Saniflo Hygienic Series Clamped Metal Pumps are uniquely designed for high-cleanliness requirements and feature a free-draining flow path that enables clean-in-place (CIP) capability. The HS flow-through liquid-path design also eliminates any potential areas where product residue can be trapped and contaminate the product. They are perfect for low-acid, pasteurized and protein-based products all the way up to bio-pharmaceutical sterile processes. HS pumps also meet the highest standards and requirements in the industry, including 3A, ATEX, EC 1935/2004, FDA CFR 21.177 and USP Class VI certification is available only for Saniflo HS pumps with PTFE elastomer options.

- Featuring energy efficient Pro-Flo® SHIFT ADS

- Free-draining flow path for CIP capability

- Easy assembly with self-centering ball cages

- Permanent or rotatable stand for cleaning

- Multiple valve options: ball, mushroom, or flap for different application requirements

- Shear sensitive

- Greater flow – more gallons pumped per SCFM

|

|

|

|

|

|

| AIR INLET: | 3/4″ FNPT |

| CONNECTION TYPE: |

Tri-Clamp® |

| DIN | |

| SMS | |

| MAX PRESSURE: | 125 psi (8.6 bar) |

| VALVE OPTIONS: |

Ball |

| Mushroom | |

| Flap | |

| LIQUID INLET: | 2″ (51mm) |

| LIQUID DISCHARGE: | 2″ (51mm) |

| MAX FLOW RATE: |

Integral Piston – Full-Stroke: 148 gpm (560 lpm) |

| PTFE – Integral Piston: 116 gpm (439 lpm) | |

| TPE – EZ-Install: 141 gpm (534 lpm) | |

| PTFE – Full-Stroke: 141 gpm (534 lpm) | |

| Rubber: 152 gpm (575 lpm) | |

| MAX DIAMETER SOLIDS: |

Ball: 1/2″ (13 mm) |

| Mushroom: 1/4″ (6.4mm) | |

| Flap: 1-7/8″ (47.5mm) | |

| MAX SUCTION LIFT CAPABILITY: |

Integral Piston – Full-Stroke: DRY – 10.6′ (3.3m) | WET – 29.5′ (9.0m) |

| PTFE – Integral Piston: DRY – 7.4′ (2.3m) | WET – 29.5′ (9.06m) | |

| TPE – EZ-Install: DRY – 13.1′ (4.0m) | WET – 29.5′ (9.0m) | |

| PTFE – Full-Stroke: DRY – 12.7′ (3.9m) | WET – 29.5′ (9.0m) | |

| Rubber: DRY – 13.6′ (4.1m) | WET – 29.5′ (9.0m) | |

| DISPLACEMENT PER STROKE (1 cycle = 2 strokes): |

Integral Piston – Full-Stroke: 0.26 gal (1.0 L) |

| PTFE – Integral Piston: 0.14 gal (0.5 L) | |

| TPE – EZ-Install: 0.26 gal (1.0 L) | |

| PTFE – Full-Stroke: 0.26 gal (1.0 L) | |

| Rubber: 0.26 gal (1.0 L) |

Wetted Housings |

Non-Wetted Housings |

|||

| MATERIAL | SHIP WEIGHT | DESCRIPTION | MATERIAL | |

| 316L Stainless Steel | 109 lbs (49 kg) | Center Block | 316 Stainless Steel, Nickel-Plated Aluminum | |

| Air Valve | 316 Stainless Steel, Nickel-Plated Aluminum | |||

| Air Chamber | 316 Stainless Steel, Nickel-Plated Aluminum | |||

Elastomer Options

| Material | Temperature Limits |

|---|---|

| EPDM | -60°F to 280°F (-51°C to 138°C) |

| FKM | -40°F to 350°F (-40°C to 177°C) |

| PTFE | 40°F to 220°F (4°C to 104°C)

40°F to 300°F (4°C to 149°C) – 1/2″ (13mm) and 1″ (25mm) models only |

| Saniflex™ | -20°F to 220°F (-29°C to 104°C) |