SFP | FP2 & FP3

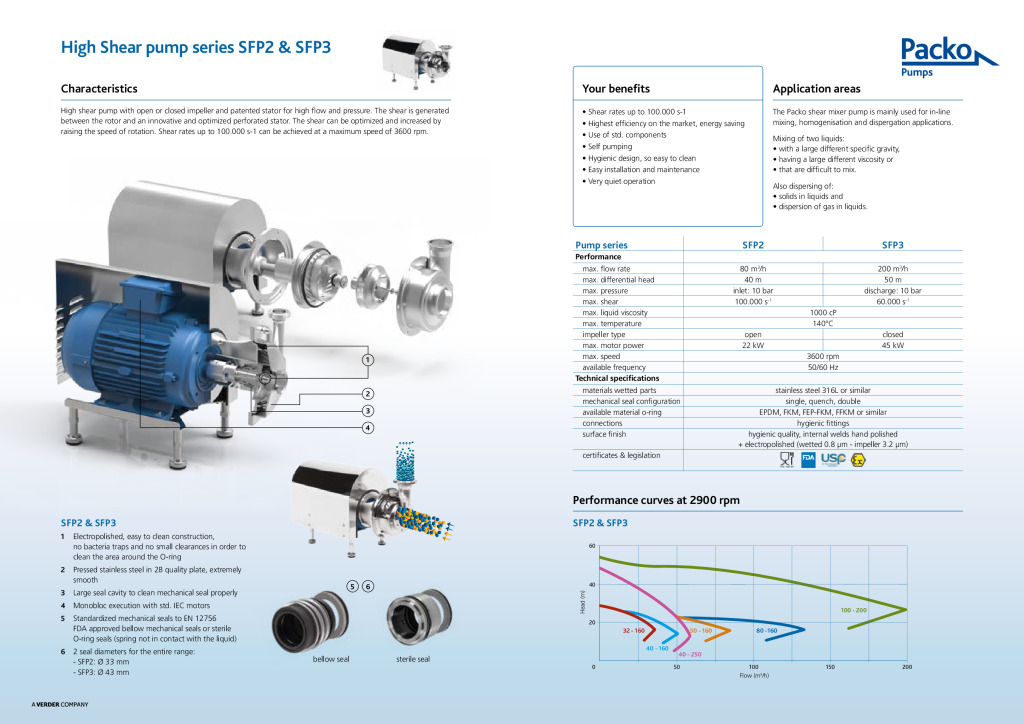

Packo SFP Characteristics :

Packo SFP Hygienic Cleanable Pumps are Based on the EHEDG certified Packo pump series FP2 with open impeller and FP3 with closed impeller.

- 1 unit for both mixing and pumping of the final liquid

- Specially designedstator with ANSYS CFD package (patented)

- Efficiency improvement between 70 and 100% compared to the currently available technologies

- Very energy efficient thanks to its high efficiency

- Quiet operation

- Electropolished, very good cleanability and high corrosion resistance. Modular concept built up with standard components. Easy installation and maintenance.

Packo SFP Hygienic Cleanable Types

| SFP | Max. flow | Max. head | Motor power up to | Max. product viscosity | Shear up to |

|---|---|---|---|---|---|

| 2/32-160 | 35 m³/h | 2.5 bar | max. 11 kW | max. 750 cP | 30.000 s-1 |

| 2/40-160 | 50 m³/h | 2.5 bar | max. 11 kW | max. 750 cP | 30.000 s-1 |

| 2/50-160 | 75 m³/h | 2.5 bar | max. 11 kW | max. 750 cP | 30.000 s-1 |

| 2/40-250 | 50 m³/h | 4 bar | max. 22 kW | max. 750 cP | 100.000 s-1 |

| 3/80-160 | 130 m³/h | 2.0 bar | max. 22 kW | max. 1000 cP | 30.000 s-1 |

| 3/100-200 | 200 m³/h | 5.0 bar | max. 45 kW | max. 1000 cP | 40.000 s-1 |

Packo SFP Hygienic Typical applications

- Mixing of 2 liquids

- with a large different specific gravity (f.i. honey in water)

- having a large different viscosity (f.i. oil in butter)

- that are difficult to mix (f.i. oil in water)

- Dispersing of solids in liquids (f.i. toothpaste in water)

- Dispersion of gas in liquids (foamed desserts)