JetTunnel Pouch Drying System for Flexible Pouch Packages

The JetAir Pouch Drying System is specifically designed to dry the entire flexible pouch package in food and beverage lines and includes integrated conveyor, dynamic hold-down, and full featured controls.

FEATURES OF THE POUCH DRYING SYSTEM:

- Complete Integrated Solution: Blower, Electrical and Material Handling

- Easy Integration on Existing Packaging Lines

- Rugged Stainless Steel Construction

- Sound Attenuation and Safety Features

- Orientates and Protects Packaging During Drying

- Dries Entire Pouch including Gussets, Spouts and Caps

- Integrates with Plant Networks and Control Schemes

- Multiple Line Lengths and Configurations

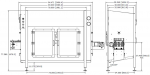

DIMENSIONS:

CASE STUDY

“In drying flexible packaging, the challenge is drying the hard-to-reach places unique to flexible packaging – the gussets and the flexible pouch undersides which collect steam condensation and are out-of-reach for a traditional pouch drying system.” – Scott Lynn, JetAir Technologies LLC, Easter Regional Sales Manager.

For years, Wornick Foods – like the rest of the flexible packaging industry – had accepted the inherent aesthetic and structural issues resulting from residual steam condensation. However, in planning a line extension, Wornick – a leading developer and supplier of convenience foods and military rations in flexible packaging – looked to eliminate this residual condensation and significantly increase production speeds. Having had success with previous JetAir drying tunnels, Wornick Foods contacted JetAir Technologies.

Based off extensive lab testing and customer feedback, JetAir’s engineering team designed a custom solution to accommodate the unique product geometry, high production rates, and handling requirements. Each configured system included 20HP JET-3 High-Speed Centrifugal Blowers, JetBlast nozzles, Variable Frequency Drives, conveyors and guiding packaged into a stand-alone tunnel.

Having extensive experience drying can tops, bottoms, and sides while traveling in mass-flow, JetAir’s engineering team designed custom conveyors with belts enabling the simultaneous drying of the pouches’ tops, bottoms, and sides at speed for a six foot length. Specially designed guiding provided the product handling and hold-down necessary to keep the product oriented for effective drying and throughput.

With the product secured, the JetAir engineering team developed a pouch handling system which fits into the conveyor frame and opens the product gussets. The design allowed the drying system access to dry all the hard-to-reach areas simultaneously. JetBlast nozzles were incorporated into the design offering higher efficient in drying irregular product surfaces than the typical use of a slotted-gap air knife. The entire system was encompassed in a stand-alone stainless steel tunnel configured to trap the spray from the residual moisture removal and reduce line noise.

The speed, efficiency, and performance of the JetAir flexible package pouch drying system exceeded Wornick’s expectations. Testing of the final design validated an increase from their original processing rate of 100 pouches per minute to over 200 pouches per minute, more than doubling previous throughput. Additionally, JetAir’s custom designed product handling and blower system offered significant improvements in Wornick’s end product results. The combination of JetAir’s flexible packaging handling and drying system effectively eliminated all residual steam condensation, including hard-to-reach areas like product undersides and gussets. As a result, related structural and aesthetic damage was eliminated, and Wornick Foods’ end product acceptance greatly improved. Elated with JetAir Technologies’ system’s speed, performance, and efficiency, Wornick Foods ordered three more systems to implement their production designs.

Click Here – For more JetAir Products

www.jetairtech.com