A-T Controls Triac F23 F26 Series 2-Piece Seal Welded Fire Safe High Pressure Ball Valves

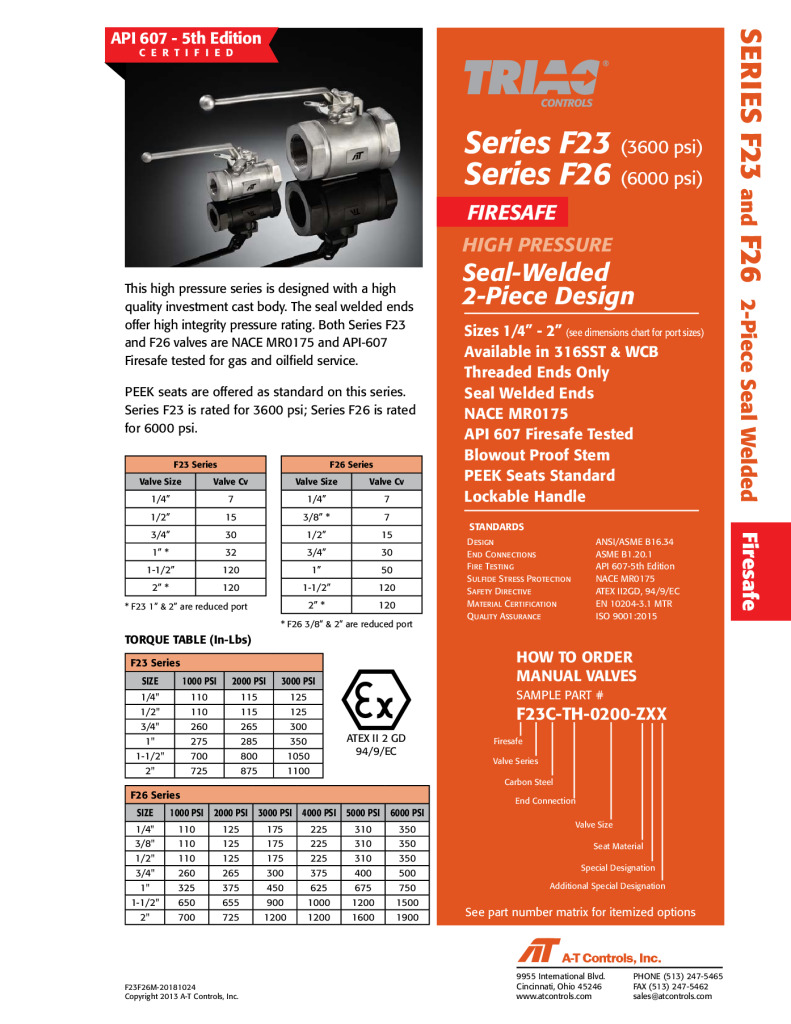

A-T Controls Triac F23 F26 Series high pressure series is designed with a high quality investment cast body. The seal welded ends offer high integrity pressure rating. Both Series F23 and F26 valves are NACE MR0175 and API-607 Fire Safe tested for gas and oilfield service.

PEEK seats are offered as standard on this series. Series F23 is rated for 3600 psi and Series F26 is rated for 6000 psi.

A-T Controls Triac F23 F26 Series Features:

- Sizes 1/4” – 2”

- Available in WCB & 316 SST

- Threaded Ends Only

- Blowout Proof Stem

- Lockable Handle

- Seal Welded Ends

- NACE MR0175

- API607 Fire Safe Tested

- PEEK Seats Standard

A-T Controls Triac F23 F26 Series Ball Valves Port Size Chart

| F23 SERIES | F26 SERIES | |||

|---|---|---|---|---|

| VALVE SIZE | PORT | VALVE SIZE | PORT | |

| 1/4″ | Full | 1/4″ | Full | |

| 1/2″ | Full | 3/8″ | Regular | |

| 3/4″ | Full | 1/2″ | Full | |

| 1″ | Regular | 3/4″ | Full | |

| 1-1/2″ | Full | 1″ | Full | |

| 2″ | Regular | 1-1/2″ | Full | |

| 2″ | Regular | |||

Manual Ball Valve Part Number Matrix

| HOW TO ORDER MANUAL VALVES (ie. ATC-F – 88 C – TH – 0150 – XXX) |

||||||||

| 1 | – 2 | 3 | – 4 | – 5 | – 6 | 7 | 8 | 9 |

| ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ | ↓ |

| ATC-F | – 88 | C | – TH | – 0150 | – X | X | X | |

1 Prefix |

4 End Connection |

|||

| ATC-F | Fire Safe Tested | TH | NPT Ends | |

| ATC-F | (on 31 Series) Graphite Packing & Seals | SW | Socket Weld Ends | |

| ATC-T | (on 31 Series) TFM Packing & Seals | BW | Butt Weld Ends | |

| ATC-NS | NSF 61 & 372 Certified Series | EW | Extended Butt Weld Ends | |

| F1 | 150# Flanged Ends | |||

2 Valve Series |

F3 | 300# Flanged Ends | ||

| 10 | 1pc. Regular Port 2000 WOG | F6 | 600# Flanged Ends | |

| 20 | 2pc. Full Port 1000 WOG | FR | 600# RTJ Flanged Ends | |

| 21 | 2pc. Regular Port 2000/1500 WOG | SA | Sanitary Clamp Ends | |

| 22 | 2pc. Direct Mount 1000 WOG, Full Port | SF | Sanitary Clamp Ends w/ Cavity Filler | |

| 23 | 2pc. 3600 WOG, Seal-Welded | DA | Tube O.D. Ends | |

| 24 | 2pc. 3000 WOG | DF | Tube O.D. Ends w/ Cavity Filler | |

| 26 | 2pc. 6000 WOG, Seal-Welded | DS | Sanitary Clamp x Tube O.D. Ends | |

| 30 | 3-Way Flanged, Full Port | TE | NPT x Extended Butt Weld | |

| 31 | 3-Way Flanged, Direct Mount, Full Port | TS | NPT x Socket Weld | |

| 33 | 3, 4, 5-Way Full Port, Multiport | MF | Male NPT x Female NPT | |

| 38 | 3-Way NPT, Regular Port | Tube Socket Weld | ||

| 55 | 3pc. 1000/800 WOG, Full Port | W1 | 150# Wafer | |

| 77 | 3pc. 1000/800 WOG, Full Port, Sanitary | W3 | 300# Wafer | |

| HP | 3pc. Forged High Purity | W6 | 600# Wafer | |

| H78 | 3pc. Cast High Purity, Encapsulated Bolts | |||

| 83 | 3pc. 2000/1500 WOG, Full Port |

5 Valve Size |

||

| 8R | 3pc. 2000/1500 WOG, Regular Port | 0025 | 1/4″ | |

| 88 | 3pc. Direct Mount 2000/1500/1000 WOG, Full Port | 0038 | 3/8″ | |

| R8 | 3pc. Direct Mount 2000/1500 WOG, Regular Port | 0050 | 1/2″ | |

| 90 | 2pc. Flanged Full Port (Investment Cast) | 0075 | 3/4″ | |

| 91 | Unibody Regular Port Flanged | 0100 | 1″ | |

| 93 | 2pc. Flanged Full Port (Sand Cast) | 0125 | 1-1/4″ | |

| V7 | 3pc. Sanitary, V-Port | 0150 | 1-1/2″ | |

| V8 | 3pc. V-Port | 0200 | 2″ | |

| V9 | Flanged V-Port | 0250 | 2-1/2″ | |

| D9 | Direct Mount Flanged | 0300 | 3″ | |

| T5 | Tank Bottom 3pc. | 0400 | 4″ | |

| C8 | Cryogenic 3pc. Full Port | 0600 | 6″ | |

| CR | Cryogenic 3pc. Regular Port | 0800 | 8″ | |

| DR | 3-Way Bottom Entry Diverter Valve | 1000 | 10″ | |

| LB | PFA Lined Split Body Flanged Ball Valve | 1200 | 12″ | |

| P1 | Schedule 10 Piggable Valve | |||

| MU | Metal Seat Unidirectional Shutoff, Floating Ball |

6 Seat, Lining & Trim Materials |

||

| MB | Metal Seat Bidirectional Shutoff, Floating Ball | X | Reinforced TFE Seats (RTFE) | |

| MS | Metal Seat Scraper Seat Design | P | Virgin TFE (PTFE) | |

| MX | Metal Seat 3 pc. Bidirectional, Floating Ball | U | UHMWPE Seats | |

| M3 | 3-Way Metal Seat | D | Delrin® | |

| VS | Segment V-Port, Soft | S | 50/50 STFE Seats | |

| VM | Segment V-Port, Metal Graphite Packing | C | 25% CS Powder/ 75% TFE Seats (CTFE) | |

| VV | Segment V-Port, Metal Viton® Packing | T | TFM™-1600 | |

| WB | Block and Bleed Isolation Valve, 2000 WOG | F | TFE Cavity Filler | |

| W6 | Block and Bleed Isolation Valve, 6000 WOG | K | PCTFE (Cryogenic) | |

| L | PFA Lined w/ PTFE Seats | |||

3 Body Material |

M | MG1241 | ||

| Blank | No Designation=SST Body and Trim | Z | PEEK | |

| A | Alloy 20 | 2 | Tungsten Carbide Coated 316 SST Seats & Ball | |

| C | Carbon Steel Body | 3 | HCr Coated Ball/Stellite® Inlay Seats | |

| L | Low Carbon 316L Stainless Steel | 4 | Chrome Carbide Coated 316 SST Seats & Ball | |

| J | Low Carbon 304 Stainless Steel | 8 | Inconel® 718+CrC | |

| H | Carbon Body /Hastelloy Ball & Stem | |||

| Q | Carbon Steel Body/Monel Ball & Stem |

7 Special Designation |

||

| R | 316 SST Body/Monel Ball & Stem | X | No Specials | Series Standard | |

| T | Hastelloy C-276 Body & Trim | G | Gear Operator | |

| E | Electropolished Stainless Steel | L | Lockable Handle (HP Series) | |

| Z | Epoxy Coated Carbon Steel | R | Regular Port Valve | |

| D | CD3MN Duplex SST | O | Oval Handle (Available on Some) | |

| G | CE3MN Super Duplex SST | S | Spring Return Handle (Direct Mount Only) | |

| 2 | F316L (SF4) Electropolished Forged | |||

| 3 | CF3M (SF4) Electropolished Cast | |||

| 4 | F316H Forged | |||

| 5 | LCB | |||

| 8 | LCC | |||

| 6 | WC6 | |||

| 9 | WC9 | |||

8 Additional Specials |

9 Special Designation |

|||

| X | No Specials | Series Standard | Blank | No Designation, SST Stem | |

| O | Oxygen Cleaned | 3 | 30° V-Port (V-ball) | |

| Z | Special End Configuration | 6 | 60° V-Port (V-ball) | |

| V | Vented Ball | 9 | 90° V-Port (V-ball) | |

| E | Bonnet Extension Lockable Handle | A | A 17-4 PH® Stem | |

| F | Fugitive Emissions Bonnet | B | XM-19 (Nitronic 50) Stem | |

| D | Degreased & Bagged | C | Duplex 2205 Stem | |

| D | Inconel® 718 Stem | |||

| L | L-Port 3-Way Arrangement | |||

| T | T-Port 3-Way Arrangement | |||

| K | FFKM O-Ring (31 Series) | |||

| X | No Specials, Standard (HP/H78 Series) | |||

| S | Anti-Static Option (HP/H78 Series) | |||